SPRINGFIELD ARMORY SA-35

Known throughout the world, the Hi-Power has always displayed a classic elegance that shooters and enthusiasts seem naturally drawn to. The intuitive ergonomics incorporated in this Browning design along with the slender slide and natural grip shape make the gun an easy choice for those wanting a steel framed 9mm with a larger magazine capacity.

In late 2021 Springfield Armory released their version of the Hi-Power aptly named the SA-35. Upon its release I was sent a gun from Springfield to have a look through, shoot, and see what I thought. This quickly turned into a request from Springfield to work the gun over with one caveat; Springfield requested I do as much as I could to the gun while retaining as many of the factory parts as possible. Normally there are items I want to change by default, but their request seemed like a challenge of sorts, one that might actually require a bit of creativity and problem solving, and I very much like a challenge and problem solving.

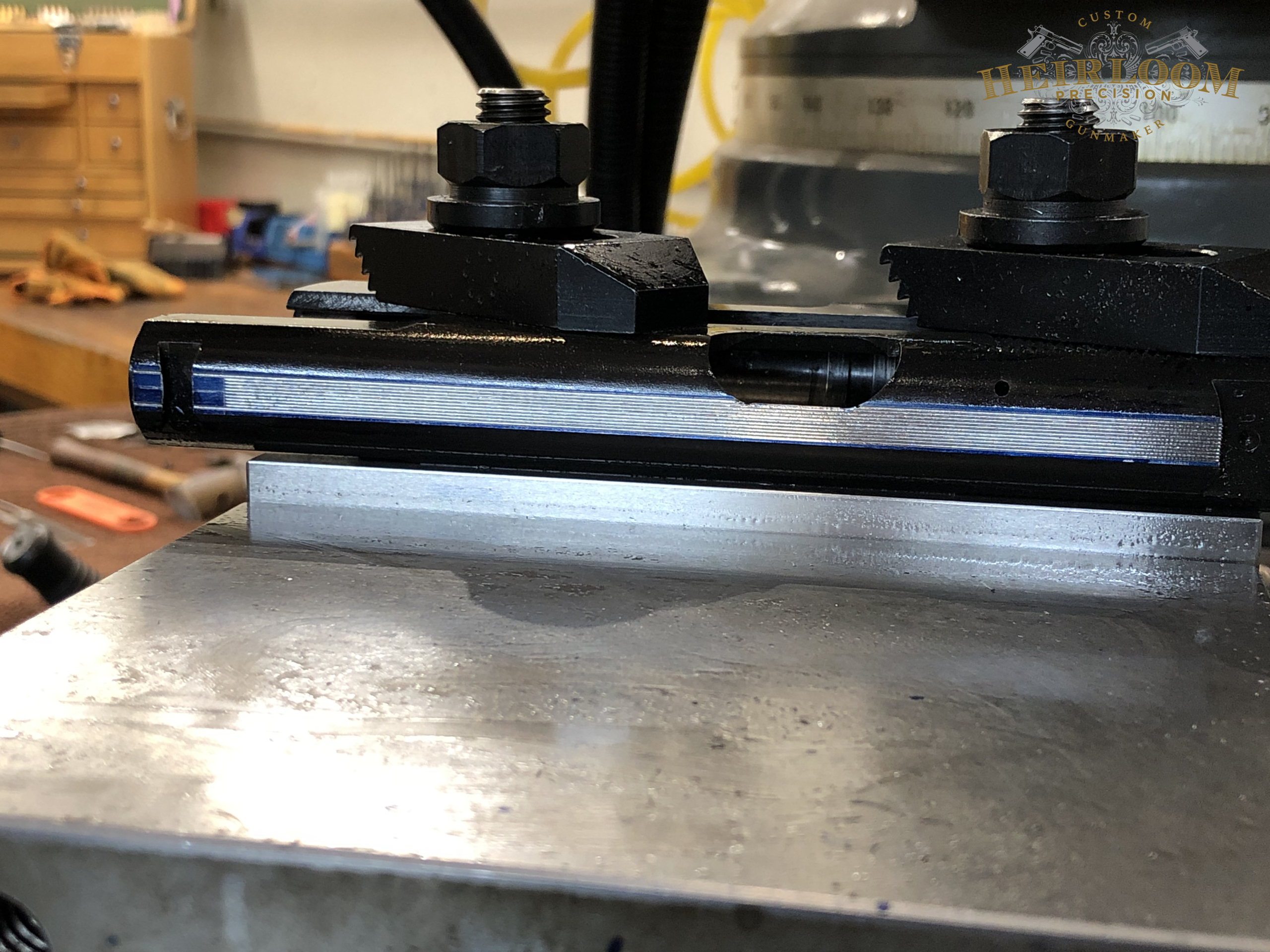

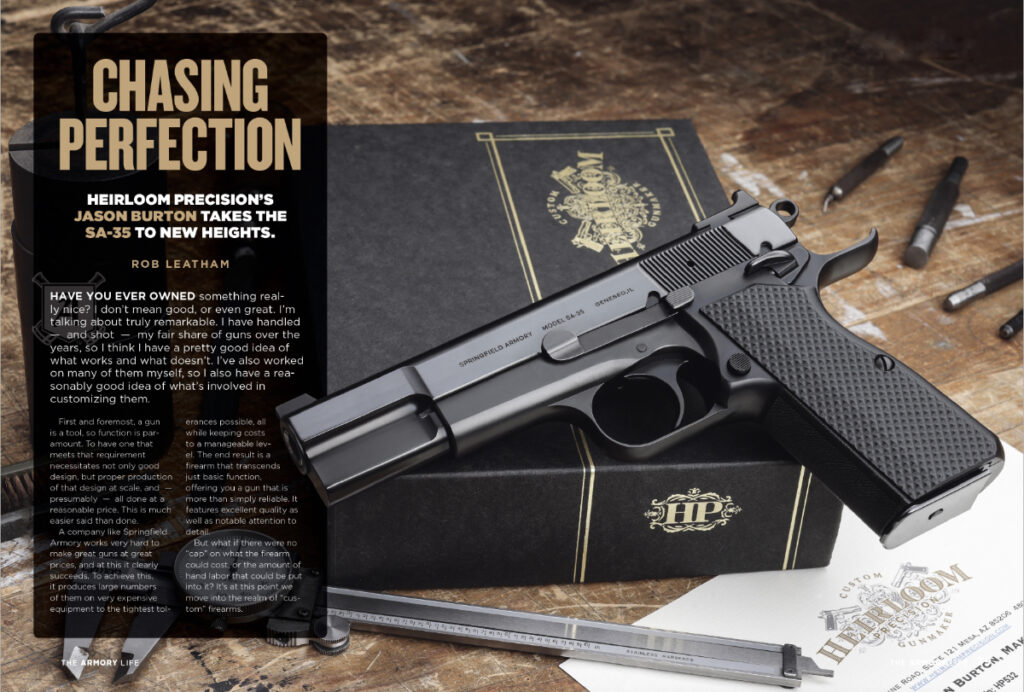

The classic profile of the Hi-Power lends itself to tasteful, well thought out modifications that can enhance the performance and usability of the Hi-Power. For the SA-35 project the slide was flattened and serrated with new sights installed into newly machined dovetails. A complete action job was performed with the addition of hard stops that reduce the travel of the trigger by limiting over-travel and reset length. The trigger face was polished along with a full reliability work-up the magazine well was beveled to allow the largest possible opening. The thumb safety lever and backing plate were reshaped and the entire part de-horned while the detent pockets in the frame were modified for positive engagement. The magazine release was also addressed to insure it could not ‘trap’ magazines and the face was machined to an angle and hand-checkered at 40lpi.

The biggest ergonomic gains, however, were made on the frame with the addition of 50lpi hand-cut checkering on the front strap and back strap as well as a welded on beavertail. Before checkering the frame the front strap was high-cut under the trigger guard which compliments the higher grip allowed by the beavertail. The beavertail itself started as a block steel that I welded onto the frame and then shaped to facilitate a solid grip on the pistol and accommodate the Springfield hammer. The hammer was lightened, shortened, and profiled as well as modified with a hard stop that prevents any contact with the newly added beavertail.

Once the entire gun was thoroughly de-horned, the complete pistol was detail prepped with a polished slide and matte frame and finished in traditional bluing. While the P35 platform is certainly not the bulk of my work, it remains a great pistol for the client wanting bespoke representation of Browning’s other masterpiece.